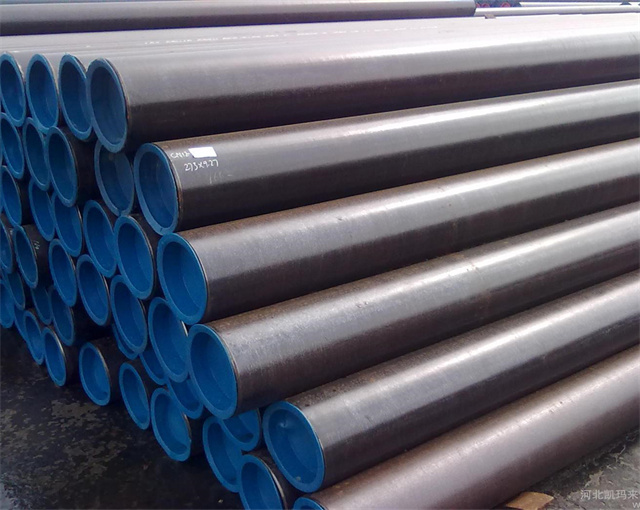

DIN 17175 15Mo3 Seamless Carbon Pipe

15Mo3 seamless steel pipe is a high-quality alloy steel pipe, mainly composed of chromium, and other elements.

| Grade | Grade A | Grade B | Grade C |

| Carbon max. % | 0.25 | 0.30* | 0.35* |

| *Manganese % | 0.27 to 0.93 | *0.29 to 1.06 | *0.29 to 1.06 |

| Phosphorous, max. % | 0.035 | 0.035 | 0.035 |

| Sulfur, max. % | 0.035 | 0.035 | 0.035 |

| Silicon, min.% | 0.1 | 0.1 | 0.1 |

| Chrome, max. % | 0.4 | 0.4 | 0.4 |

| Copper, max. % | 0.4 | 0.4 | 0.4 |

| Molybdenum, max. % | 0.15 | 0.15 | 0.15 |

| Nickel, max. % | 0.4 | 0.4 | 0.4 |

| Vanadium, max.% | 0.08 | 0.08 | 0.08 |

| Grade | Grade A | Grade B | Grade C |

| Tensile Strength, min., psi | 48000 | 60000 | 70000 |

| Yield Strength, min., psi | 30000 | 35000 | 40000 |

| ASTM A106 Steel Grade | Tenssile Test MPa or N/mm2 | |

| MIn. Yield Point | Tensile Strength | |

| Grade A | 205 | 330Min |

| Grade B | 240 | 415Min |

| Grade C | 275 | 485Min |

| Specification | Mechanical Properties | Grade A | Grade B | Grade C |

| ASTM A53 | Tenside strength, min, psi (MPa) | 48000(330) | 60000(415) | |

| Yield strength, min, psi (MPa) | 30000(205) | 35000(240) | ||

| ASTM A106 | Tenside strength, min, psi (MPa) | 48000(330) | 60000(415) | 70000(485) |

| Yield strength, min, psi (MPa) | 30000(205) | 35000(240) | 40000(275) |

| Heat Treatment | Hot-finished pipe need not be heat treated. Cold-drawn pipe shall be heat treated after the final cold draw pass at a temperature of 1200 °F (650 °C) or higher. |

| Process |

|

| Surface Treatment | Oil-dip, Varnish, Passivation, Phosphating, Shot Blasting |

| Hydrostatic Testing | Inspection test pressures produce a stress in the pipe wall equal to 60% of specified minimum yield strength (SMYS) at room temperature. Maximum Pressures are not to exceed 2500 psi for NPS3 and must stay under 2800 psi for the larger sizes. Pressure is maintained for not less than 5 seconds. |

| Nondestructive Electric Test | The full body of each pipe shall be tested with a nondestructive electric test in accordance with Practice E 213, E 309, or E 570. |

| Mechanical Tests Specified |

|