Stainless steel hydraulic pipes are usually made of corrosion-resistant stainless steel, such as

304,

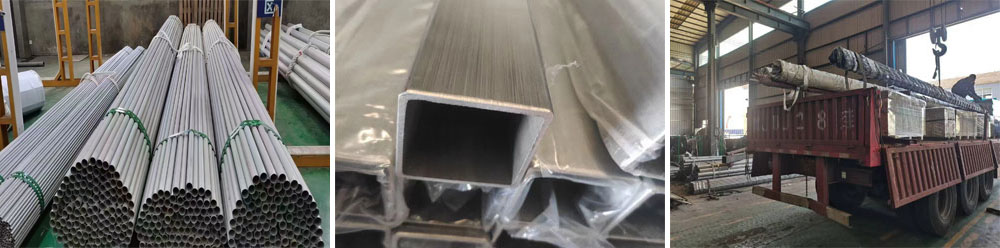

316, 316L, etc. These stainless steel materials have excellent corrosion resistance and can maintain good performance in humid, acidic and alkaline environments and are not easily corroded. Due to the corrosion resistance of stainless steel, stainless steel acid-resistant pipes are widely used in situations that require high corrosion resistance of pipes. It can resist the erosion of water, acid, alkali and other corrosive media, effectively extending the service life of the pipeline.

Stainless steel pipes have sufficient strength and pressure resistance to withstand the high pressures commonly found in hydraulic systems. It ensures the stable operation of the hydraulic system and prevents damage caused by pressure fluctuations. In order to improve its surface finish and corrosion resistance, the surface usually needs to be properly treated, such as polishing, pickling, etc.

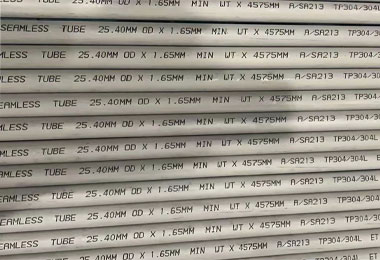

Standard specifications: The production and use of stainless steel hydraulic pipes must comply with specific standards and specifications, such as ASTM A269, ASTM A312, etc. These standards stipulate the chemical composition, mechanical properties and manufacturing process of pipes, ensuring product quality and reliability.

.jpg)

.jpg)

.jpg)