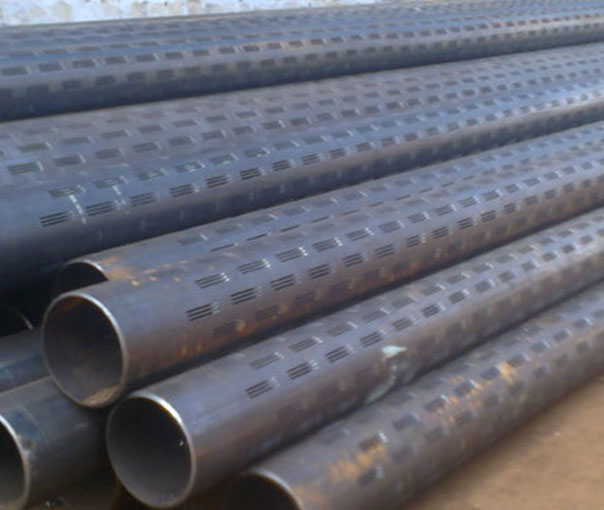

LINE PIPE

Casing is a large-diameter pipe that serves as the structural retainer for the walls of oil and gas wells, or well bore.

| API Casing pipe | ID mm |

Length m |

Slot Length mm |

Slot No. No./m |

Slot width mm |

Slot Tolerance |

Valid Filter Area cm/m |

Max. Strength KN |

||

| Spec mm |

Thickness mm |

Per Weight kg/m |

||||||||

| 60.32 | 5 | 6.84 | 50.3 | 3 | 80 | 200 | 0.3 | ±50 | 48 | 512.54 |

| 73.02 | 5.5 | 9.15 | 62 | 240 | 57.6 | 688.55 | ||||

| 88.9 | 6.5 | 13.22 | 75.9 | 280 | 67.2 | 995.1 | ||||

| 101.6 | 6.5 | 15.22 | 88.6 | 300 | 72 | 1151.2 | ||||

| 114.3 | 7 | 18.47 | 100.3 | 10 | 320 | 76.8 | 1400.4 | |||

| 127 | 7.52 | 22.13 | 112 | 340 | 81.6 | 1673.8 | ||||

| 139.7 | 7.72 | 25.11 | 124.3 | 360 | 86.4 | 1900.2 | ||||

| 9.17 | 29.48 | 121.4 | 360 | 86.4 | 2232.4 | |||||

| 168.3 | 8.94 | 35.09 | 150.4 | 400 | 96 | 2672.95 | ||||

| 177.8 | 8.05 | 33.68 | 161.7 | 440 | 105.6 | 2559.2 | ||||

| 9.19 | 38.19 | 159.4 | 440 | 105.6 | 2940.7 | |||||

| Sreen pipe dimension (in) | OD(mm) | Wall thickness(mm) | ID (mm) | Stitch number of each circle | Slot width(mm) | Slot length (mm) | Length(mm) |

| 2-3/8″ | 60.3 | 4.83 | 50.64 | 12~18 | 0.2~0.8 | 45~100 | 1000~12000 |

| 2-7/8″ | 73 | 5.51 | 61.98 | 20~24 | 45~100 | ||

| 3-1/2″ | 88.9 | 6.45 | 76 | 24~28 | 45~100 | ||

| 4″ | 101.6 | 6.65 | 88.29 | 24~30 | 45~100 | ||

| 4-1/2″ | 114.3 | 5.69 | 102.92 | 24~30 | 45~100 | ||

| 6.35 | 101.6 | 45~100 | |||||

| 7.37 | 99.57 | 45~100 | |||||

| 8.56 | 97.18 | 45~100 | |||||

| 5″ | 127 | 5.59 | 115.82 | 28~36 | 0.25~0.8 | 45~100 | |

| 6.43 | 114.15 | 45~100 | |||||

| 7.52 | 111.96 | 45~100 | |||||

| 9.19 | 108.61 | 45~100 | |||||

| 5-1/2″ | 139.7 | 6.2 | 127.3 | 30~38 | 45~100 | ||

| 6.99 | 125.73 | 45~100 | |||||

| 7.72 | 124.26 | 45~100 | |||||

| 9.17 | 121.36 | 45~100 | |||||

| 10.54 | 118.62 | 45~100 | |||||

| 7″ | 177.8 | 6.91 | 163.98 | 36~50 | 45~100 | ||

| 8.05 | 161.7 | 45~100 | |||||

| 9.19 | 159.41 | 45~100 | |||||

| 10.36 | 157.07 | 45~100 |

| Standard | Grade | Chemical compositions(%) | |||||||||

| API SPEC 5CT | J55 | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 | 0.34~0.39 | 0.20~0.35 | 1.25~1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | |

| N80 | 0.34~0.38 | 0.20~0.35 | 1.45~1.70 | ≤0.020 | ≤0.015 | ≤0.15 | / | / | / | 0.11~0.16 | |

| L80 | 0.15~0.22 | ≤1.00 | 0.25~1.00 | ≤0.020 | ≤0.010 | 12.0~14.0 | ≤0.20 | ≤0.20 | / | / | |

| P110 | 0.26~0.395 | 0.17~0.37 | 0.40~0.70 | ≤0.020 | ≤0.010 | 0.80~1.10 | ≤0.20 | ≤0.20 | 0.15~0.25 | ≤0.08 | |

| Grade | Type | Total elongation under load (%) | Yield strength (min) | Yield strength (max) | Tensile strength min Mpa | Hardness Max (HRC) | Hardness Max(HBW) |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| C90 | - | 0.5 | 621 | 724 | 689 | 25.4 | 255 |

| C95 | - | 0.5 | 655 | 758 | 724 | - | - |

| T95 | - | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | - | 0.6 | 758 | 965 | 862 | - | - |

| Q125 | All | 0.65 | 862 | 1034 | 931 | - | - |