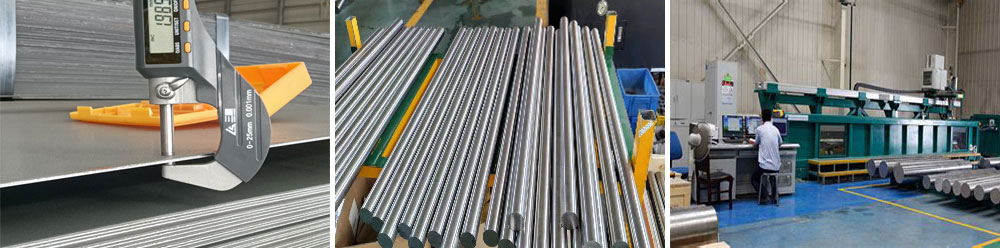

ALLOY SEAMLESS PIPE

The Alloy Steel Seamless Pipe is used in applications that require high precision for installation ease and for the accuracy of the operation and application.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)