product introduction

Short Description:

Material:CP titanium, Titanium alloy

Grade:Gr1, Gr2, Gr4, Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 etc

Size:OD: 0.6~13mm,Max length:4m; OD: 13~120mm,Max length:15m;WT: 0.3~12mm

Standard:ASTM B338, ASTM B337, ASTM B861, ASTM B862 etc

Status:Annealed (M)

Technology:Rolling, Welding, Machining

Form:Round, Square, Rectangular, Coil, U Tube

End:Plain End, Bevelled End

Surface:Black painting, varnish paint, anti rust oil, hot galvanized, cold galvanized, 3PE

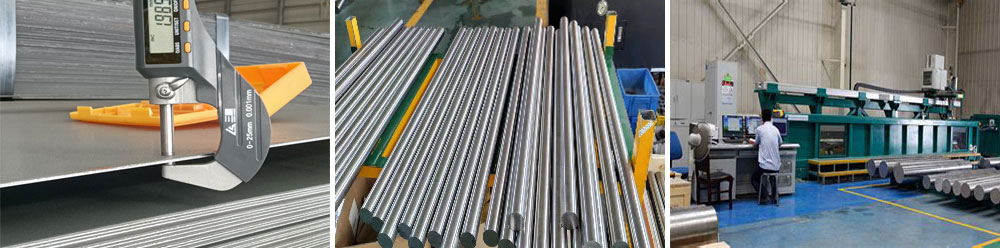

Titanium seamless tube is processed by the breakdown of titanium ingot, extruding to titanium tube billet. Then produce titanium tubes to appropriate size with series of processes such as multiple rolling, annealing, pickling, and grinding technology.

Titanium welded tube is by selecting a suitable thickness of the high quality cold rolled titanium plate, after the process of flattening, cutting and washing, then rolled up titanium plate into tubular, welding by the whole automatic welding equipment. Our advanced welding equipment guaranteed the quality of welding. Ultimately help to produce the excellent quality titanium tube.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)